Maximizing Warehouse Efficiency: How Smart Lighting and Automation Can Make Your Warehouse Run Smoother

- Otto Solutions Pte Ltd

- Sep 25, 2024

- 3 min read

Updated: Feb 17

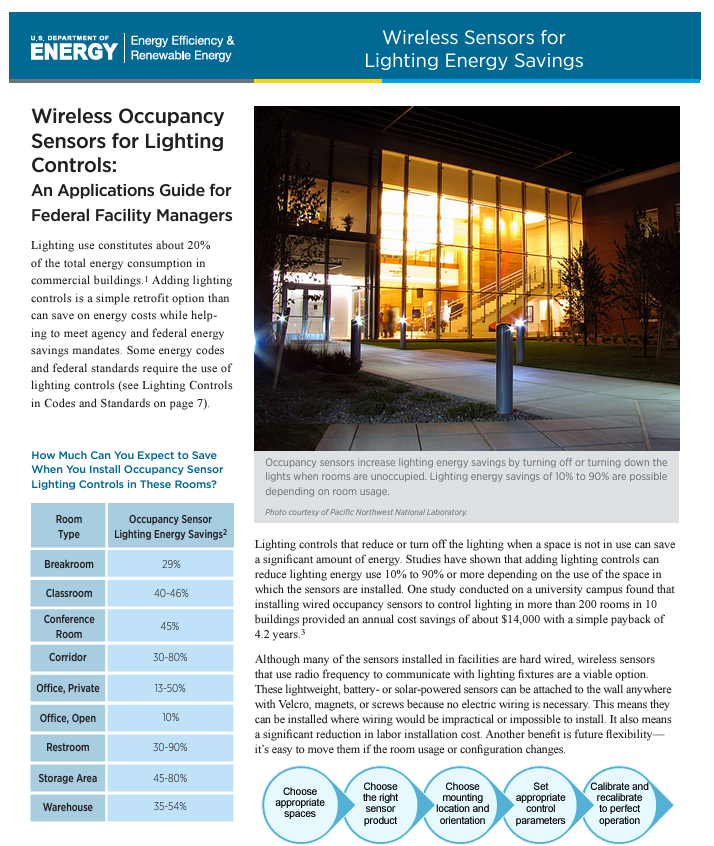

In the fast-moving world of logistics, warehouses play a crucial role in ensuring the smooth flow of goods. But with tight schedules, massive inventories, and 24/7 operations, maintaining efficiency can be a challenge. One area that is often overlooked but plays a vital role in optimizing operations is ENERGY MANAGEMENT. As warehouses strive to improve efficiency, managing energy consumption and environmental conditions becomes increasingly important. This is where smart lighting, automation, and integrated systems step in, offering solutions that not only reduce energy costs but also create a more sustainable, comfortable environment.

The Challenge of Warehouse Efficiency

Warehouses and logistics centers are essential components of the global supply chain. These facilities operate non-stop, handling goods and maintaining tight schedules. However, traditional systems, such as outdated lighting, heating, ventilation, and air conditioning (HVAC) systems, often work independently, leading to inefficiencies. Poorly managed energy consumption, suboptimal indoor air quality (IAQ), and outdated equipment increase operational costs and reduce workplace productivity.

Energy consumption is one of the biggest challenges, with lighting and HVAC systems accounting for a significant portion. In many warehouses, lights stay on even when areas are unoccupied, and HVAC systems run at full capacity regardless of the conditions inside the building. This lack of coordination between systems leads to energy waste, higher costs, and a less-than-ideal working environment for employees.

Another milestone unlocked! Thank you Kerry Logistics for trusting OTTO Solutions and its subsidiary Group.

Smart Solutions for Better Efficiency

At OTTO Solutions, we offer a comprehensive approach to improving warehouse efficiency by integrating advanced lighting control, sensors, and automated systems. Powered by BZERO Technologies and Lighting Solutions, our solutions focus on optimizing energy use, improving indoor air quality, and reducing costs.

Here’s how:

1. Smart Lighting Systems. Our smart lighting systems use sensors to ensure lights are only active when necessary. With passive infrared (PIR) occupancy sensors, lighting automatically adjusts based on real-time data. If no movement is detected, the lights dim or turn off, significantly cutting energy waste. We also incorporate daylight harvesting, which adjusts artificial lighting based on the amount of natural light entering the warehouse. This ensures optimal lighting conditions while minimizing energy usage.

2. Automatic Scheduling for Efficiency. Warehouses often see fluctuations in activity levels, especially during holidays or off-hours. Our systems allow for automatic on/off scheduling for lighting and HVAC systems. This means energy consumption is minimized during non-working periods, such as weekends and holidays, without the need for manual intervention. Yes, you read it right - all you have to do is update the schedule mode and what you need is just just a a few clicks from your dashboard.

3. ACMV Automation and Monitoring. To further reduce energy waste, we install sensors that monitor the performance of air conditioning and mechanical ventilation (ACMV) systems. These sensors provide real-time data that allows for automation, adjusting HVAC operations based on occupancy and IAQ conditions. This keeps the environment comfortable while ensuring systems aren’t running unnecessarily.

4. Indoor Air Quality (IAQ) Management. This solution, being optional in nature is often overlooked, but good air quality is crucial for both the health of employees and the protection of stored goods. Our IAQ sensors monitor important parameters such as temperature, humidity, and CO2 levels. By continuously analyzing this data, the system can make adjustments to ventilation and air conditioning, ensuring optimal conditions for workers and products alike.

5. Integrated Systems with SCADA and BMS. One of the most powerful aspects of our solutions is the integration of systems using SCADA (Supervisory Control and Data Acquisition) and BMS (Building Management System) technology. This integration allows for centralized monitoring and control of lighting, HVAC, and other critical systems. Facility managers can access real-time data, allowing them to identify inefficiencies, address anomalies, and optimize performance quickly.

Energy Savings and Operational Impact

The adoption of smart lighting, automated HVAC systems, and integrated controls has a measurable impact on energy savings in warehouses. According to the U.S. Department of Energy, using advanced lighting controls can reduce warehouse energy consumption by up to 54%. Furthermore, optimizing HVAC operations through automation and IAQ monitoring can lead to an additional 20-30% in energy savings.

These solutions not only reduce energy costs but also create a more comfortable work environment. By maintaining better air quality and consistent temperatures, employee productivity increases, and the quality of stored goods is protected.

Ready for the Future of Warehouse Efficiency?

In the competitive world of logistics, improving operational efficiency is key to staying ahead. With OTTO Solutions' smart lighting, ACMV automation, advanced sensors, and integrated systems, you can reduce energy costs, enhance workplace conditions, and move toward a more sustainable future.

Are you ready to transform your warehouse or logistics center? CONTACT US today to find out how our innovative solutions can help you optimize energy use, reduce costs, and create a more efficient operation.

Sources :

Comments